Recently I was able to get two 3d printers, XYZ DaVinci Mini W and Minimaker. Mainly to mess around with and do new things. Make things. But if you want to make something you have to build something. And Autodesk’s Fusion 360 is the way to go. There is a learning curve, but after a while, you start to get how things move and making things get easier.

And making things to extend a toyline is fun.

That also means you need to get a caliper measuring tool. It will make getting parts the perfect size in Fusion 360 easy.

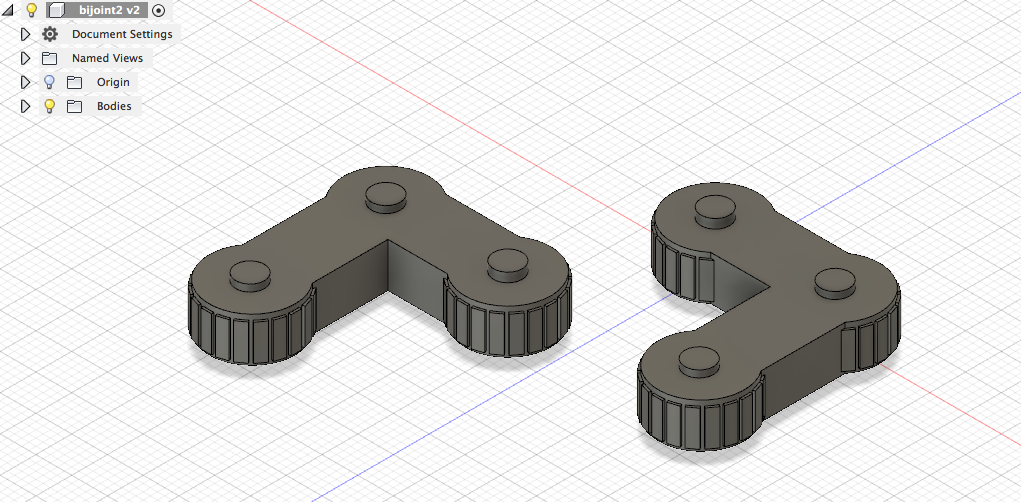

Started off making a double joint for an Acid Rain World Laurel. A mech with stubby legs and long arms. The double joint allows a secondary forearm for the mech. Simple design. This was my first practical 3D model.

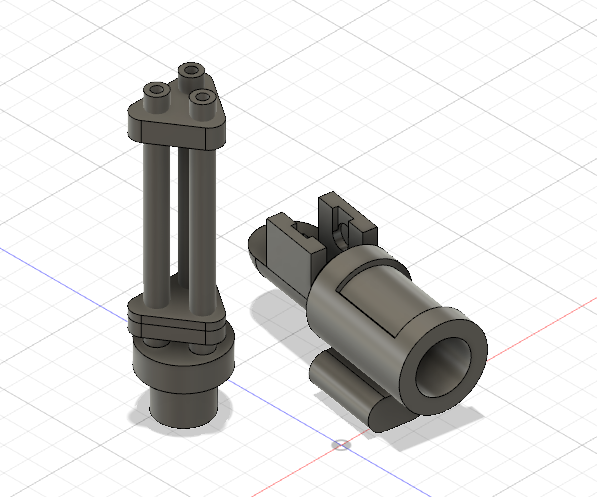

The practical model was a gattling gun forearm. Which was made in three parts: the body, the barrels and where the arm attaches to the joint.

V1 was a great size, but after looking at the design language set up by Kit Lau, the creator of Acid Rain World, it might be better to go tad nuts.

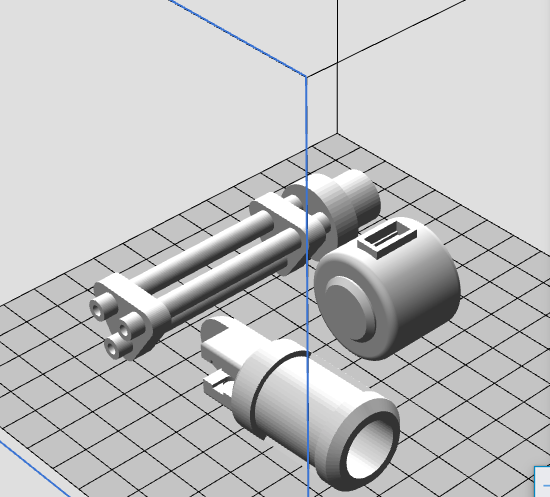

The model was increased in size by 1.5 times. The bottom round thing was replaced by a removable ammo drum.

Boy howdy, it was bigger now.

Creating these new things is opening up a new world of fun.

Starting new models for new things.

Will update soon.